Introduction

Today’s constructions need to be built fast, built strong, and built sustainably, and offer economically viable building solutions.

Builders, architects, and property owners are showing a preference for precast concrete walls for the growing number of advantages building to positive customer perceptions.

In 2025, the positive sentiments are predicted to grow and be driven by new sustainable technologies, sustainable technologies, and design innovations.

There are seven compelling rationales highlighted in the article on the reasons precast concrete walls are a viable replacement to traditional walls for your next project.

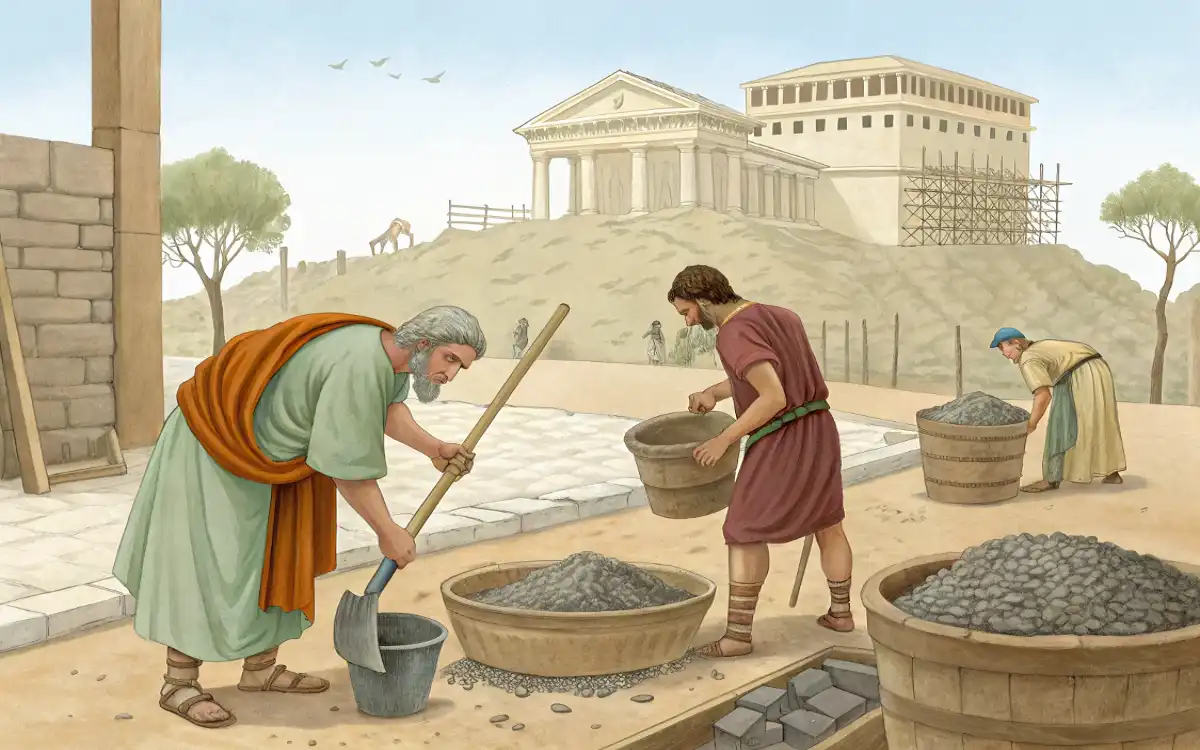

What Are Precast Concrete Walls?

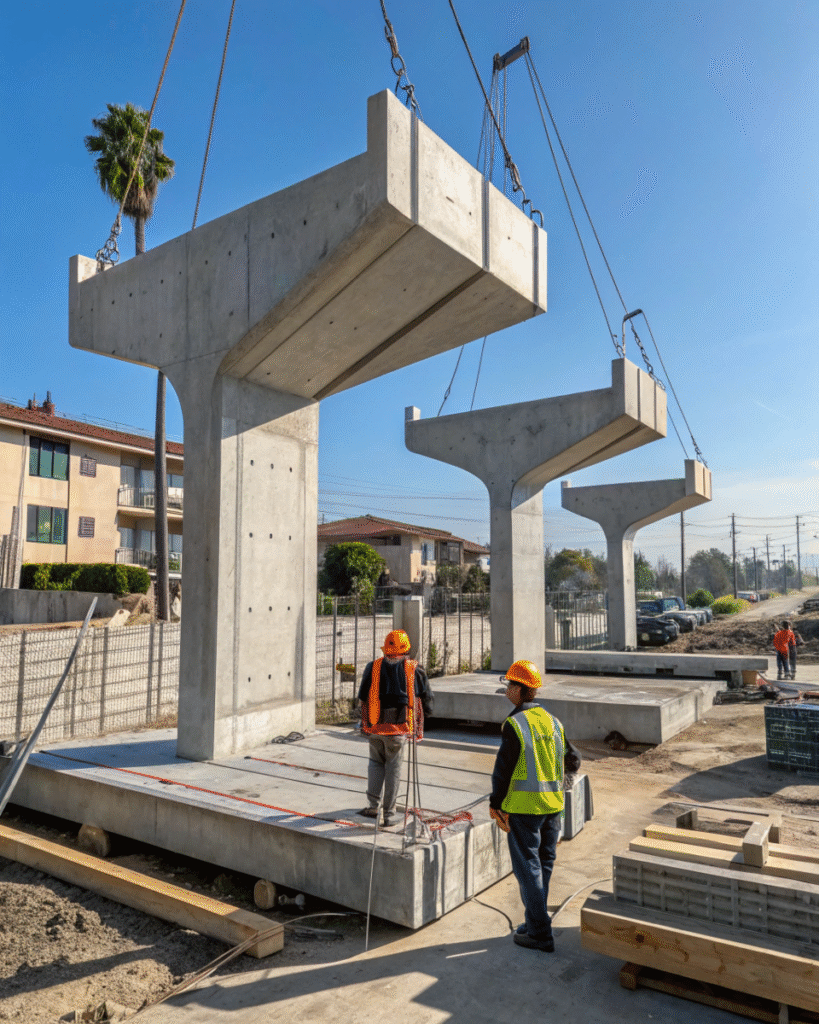

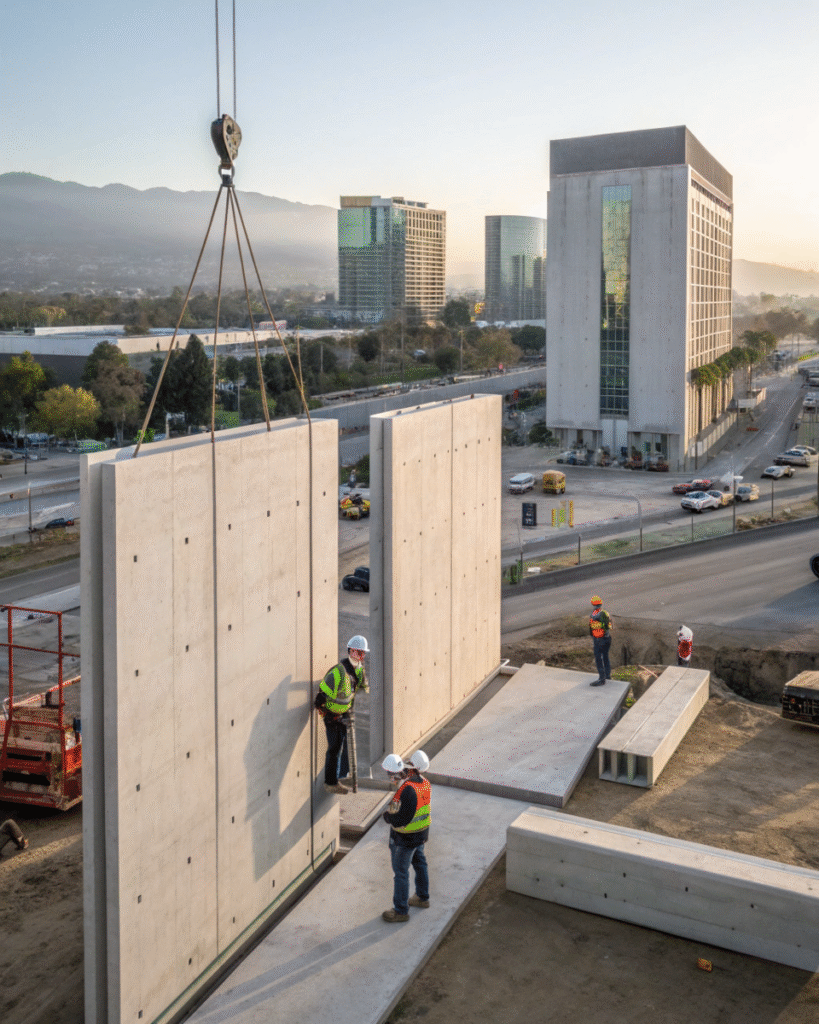

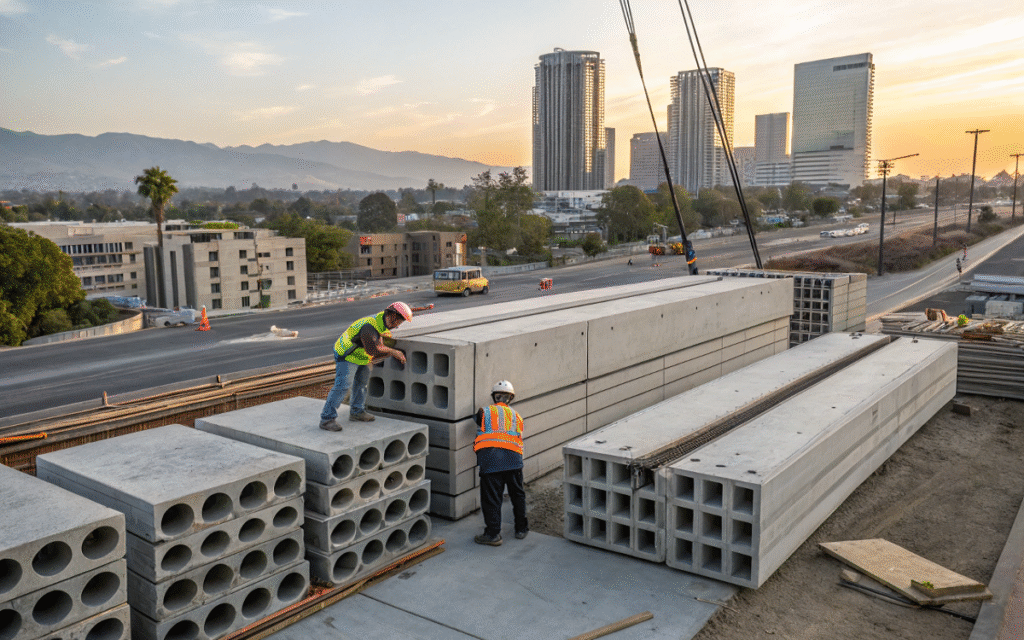

Precast concrete walls are designed and manufactured in a factory prior to being transported and installed on a construction site.

Precast walls are built using sophisticated modern technology and equipment which guarantees consistent quality, strength, and efficiency as opposed to traditional walls which are built and constructed on site.

Nowadays, for modern construction, precast walls are essential in residential, commercial, and industrial modern developments, highway projects, and smart buildings.

1. Unmatched Speed and Efficiency

Precast concrete walls spectacularly minimize installation time. Compared to conventional walls, which require a longer construction time because of on-site mixing, setting, and weather conditions, building with precast concrete walls saves time and lowers labor costs.

Precast panels are manufactured off-site, mercy west which means they are made and delivered ready to install. With precast, entire walls can be erected within days, allowing projects to stay on schedule.

Table: Precast Concrete Walls vs. Traditional Walls by Construction Speed

| Type of Wall | Typical Installation Time | Labor Required | Weather Dependency |

| Precast Concrete | 1–3 days (per section) | Moderate (fewer workers) | Minimal |

| Traditional Masonry | 7–14 days (per section) | High (skilled masons) | High |

2. Superior Durability and Strength

More than alternative construction materials, precast concrete walls are durable and strong. These walls are designed and crafted with a dense material to withstand extreme weather, heavy loads, high winds, and seismic activity.

Moisture penetration, cracks, rot, and even pests cannot compromise traditional walls made of brick, block, or poured concrete. With minimal maintenance, precast concrete walls outperform conventional ones. Over decades, they will outlast and outperform on concrete and won’t be cracked surfaces.

3. Unmatched Quality Control

Each precast concrete element’s quality control is easier to manage, given that they are made in a controlled factory environment. Each wall panel is made to specification with guaranteed uniformity in strength, quality, and measurements.

This is usually unattainable with site-mixed concrete or hand-laid masonry due to field conditions, erratic materials, and human fallibility. The precision provided by advanced molds and technology applies to accuracy, defying odds in call-backs and defects.

4. Fire, Moisture, and Pest Resistance

Precast concrete walls are non-combustible with outstanding protective fire ratings. These walls are impermeable to water; they do not rot, warp, or support mold growth. Compared to timber or drywall alternatives, they mold, rot, and warp.

They are also resistant to moisture. As a boundary or property line protective wall, this means they are a pest and termite shield, reinforcing the value of the investment. This also means peace of mind.

5. Improved Energy Efficiency

Precast modern concrete walls can be designed with integrated thermal insulation, making them even more energy efficient. The mass and density of concrete walls help in regulating temperatures.

This positive energy balance results in cooler spaces in summer and warmer spaces in winter. This limits the energy costs associated with heating and cooling.

The use of sustainable cement blends with fiber reinforcements and other sustainable materials enhances the long-term energy savings and cost-effectiveness of precast options.

6. Design Flexibility and Versatility

When it comes to precast concrete walls, there is certainly no limitation, customizations, obra of different patterns, colours and finishes can be created to meet any architectural needs.

Other than basic customizations to produce stone or brick looks, precast designs can be modified to meet any other needs.

For modern shapes and customizations, you can use software such as BIM (Building Information Modeling). This reinforces the use of precast walls in modern and traditional designs alike.

7. Cost-Effectiveness

When considering the cost of precast concrete walls, one might think that the value offered is lesser than compared with traditional building methods, however, this is not the case.

Costs offered by traditional building methods tend to add up due to lengthy installation periods, higher maintenance costs, repairs, repainting, and building upkeep over the years.

This is not true with precast panels. In fact, for large-scale projects, precast panels tend to provide cost-effective solutions as competitors tend to price them per linear foot.

Latest 2025 Industry Updates

2025 also offers new advancements to the precast concrete industry. Some new advancements include,

- Expansion of the Global Market: In 2025, the precast concrete market is expected to exceed 150 billion dollars due to market demand driven by market sustainability.

- Mandates for Precast in Road Infrastructure: India’s MoRTH mandates and policies are intended to produce faster, higher quality, and greener civil works using precast concrete for highway projects.

- Smart Technologies: Real-time structural monitoring with IoT sensors and BIM integrated design and controlled implementation are major game-changers in project management today. 3D printing in precast manufacturing allows faster design and the construction of intricate custom modules.

| Feature | Precast Concrete Walls | Traditional Walls |

| Installation Speed | Fast (days per section) | Slow (weeks per section) |

| Quality Control | High, factory-controlled | Variable, on-site |

| Durability | Very high, decades | Moderate, needs upkeep |

| Fire/Moisture Resistance | Excellent | Moderate to poor |

| Energy Efficiency | Superior (insulated) | Lower (added insulation needed) |

| Customization | High (wide finishes) | Medium (labor dependent) |

| Maintenance Costs | Low | High |

| Environmental Impact | Green (modern tech) | High (waste, emissions) |

| Labor Requirement | Fewer staff | More/skilled labor |

Concluding the Comparison of Precast and Traditional Walls

For these reasons, it is evident that the speed, durability, design versatility, and eco-friendly nature of precast walls considerably surpass the features of traditional wall construction methods.

These walls are not only technologically advanced but are also ideal for advanced global construction. These walls provide property owners a modern construction solution.

Whether it is a large scale property development, construction of a commercial facility, or simply upgrading property borders, the benefits of precast concrete is undeniably valuable.

Working with a qualified precast contractor will demonstrate real progress with every linear foot of construction of adaptable, tough concrete forms. Don’t miss the opportnity, for precast concrete walls will make your construction goals a reality.

For Repair and Services

1924 W Edward Ln, Milwaukee, WI 53209, United States

Phone: +14142855933

Email: [email protected]