Tag: precast contractor

-

Why Precast Beats Cast in Place Concrete for Modern Construction?

Posted :

by :

Introduction One of the top strategies for success in the construction industry is picking the right method of forming concrete. Between precast concrete and cast in place concrete, the latter being the traditional method, precast concrete is the method of choice in modern constructions, including places like El Monte that prioritize quality and efficiency. This…

-

Why Clayton Concrete Leads in Precast Excellence Across the USA?

Posted :

by :

Introduction to Clayton Concrete’s Industry Leadership Founded in 1951, Clayton Concrete has emerged as one of the premier ready-mix and precast concrete producers in the country. Its technology and quality control focus, along with impeccable customer service, has Clayton Concrete served to all types of construction, be it infrastructure or commercial, throughout the United States.…

-

Precast Solutions in USA: 7 Shocking Reasons Builders Are Switching Introduction

Posted :

by :

To build a thing means to put together different parts of something in order to make it whole and useable. In this case, a concrete component is what is defined as a singular unit of a construction as component parts. In the USA, the concrete in use is most often precast as it has been…

-

Block Wall Construction: 7 Incredible Benefits of Precast Concrete in 2025

Posted :

by :

Preface There are numerous precast concrete applications in construction. In 2025, new materials continue to change how buildings are designed, and constructed. This innovation in wall construction incorporates precast concrete, enabling block walls to be constructed quicker and at a reduced cost. Contractors continue to marvel at the rapid construction of block walls using precast…

-

Concrete Wall Retaining: 7 Stunning Precast Designs Transforming Modern Landscaping

Posted :

by :

Introduction In the present day, concrete wall retaining structures have gained great importance in landscaping and construction for the consideration of erosion control, attractive terraces, and maximizing usable space outdoors. As modern-day landscaping focuses on sustainable and economical methods, precast concrete is now a leading choice. Unlike poured concrete walls, retaining walls made from precast…

-

Precast Prestressed Concrete Institute: 7 Game-Changing Innovations Transforming Modern Construction

Posted :

by :

What is the Precast Prestressed Concrete Institute? Started in 1954, the Precast Prestressed Concrete Institute is a technical organization which provides support to producers, engineers, architects, educators, and contractors in the industry of precast and prestressed concrete. PCI fosters the excellence in the manufacture and utilization of precast concrete by developing standards, design handbooks, quality…

-

Things to Do in Riverside: 7 Amazing Experiences from Historic Sites to Modern Precast Concrete Designs

Posted :

by :

Introduction Riverside, California, is a city with its roots intertwined with innovation. Its history is multifaceted, with historic sites and modern constructs where elaborately designed precast concrete has become a prominent feature. If you fancy history, the outdoors, or the latest structures, there is so much to do and see in things to do in…

-

Property Line Protection Made Easy with Precast Concrete Walls for Ultimate Privacy

Posted :

by :

Introduction Protecting the property line is crucial for both privacy and security, especially as urban living density increases and property boundaries become more significant. Traditional boundary options can be expensive, slow to install, and often require frequent maintenance. Enter precast concrete walls, a rapidly growing trend transforming how properties in places like El Monte are secured and…

-

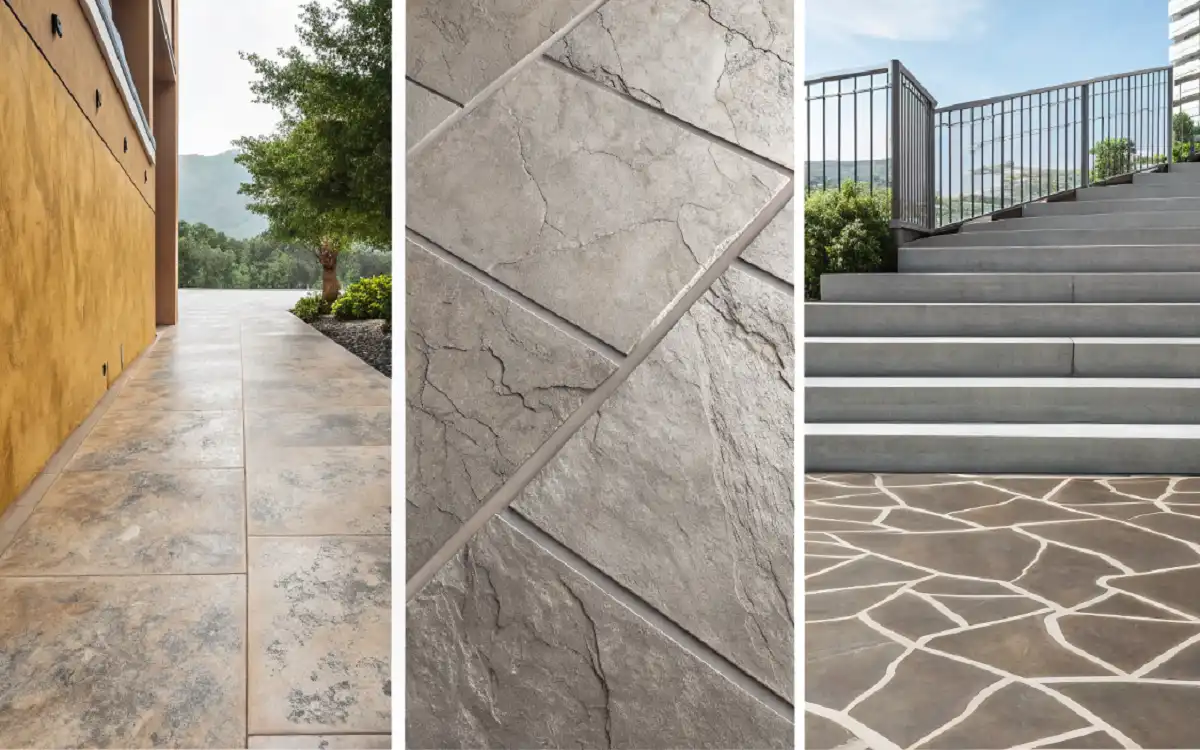

Precast Concrete Finishes: 5 Transform Modern Architecture

Posted :

by :

Introduction The use of modern architecture with sustainable and striking materials and methods is underway in the construction of buildings and other structures. An example is in the innovative custom precast concrete finishes. Concrete is fast becoming the creative focus of many architects as advanced technology sprouted concrete ‘artworks’. Smart technology coupled with 3d printing…

-

Top Things to Do in El Monte, California with a Touch of Precast Concrete Influence

Introduction El Monte is a lively city in El Monte California with interesting attractions, a rich history, and a varied community. They have parks and ancient landmarks which are great places to hang out. El Monte is a city to witness clever construction like precast concrete. El Monte is city which have slab in many…