Tag: concrete fence

-

Stabilization and Association Agreement: 5 Game-Changing Impacts on Precast Concrete Infrastructure

Posted :

by :

The Stabilization and Association Agreement (SAA) positively impacts other Western Balkan Countries (WBC) and the European Union (EU) by promoting trade and investment. In particular, the SAA contract positively affects engineering economic activities including the construction and precast concrete manufacturing industries. The SAA contract allows businesses to access and trade concrete prefabricated cement products (e.g.…

-

Architectural Design Trends 2025: The Rise of Precast Concrete Structures

Posted :

by :

Introduction Recent updates to the field of construction and architectural design are being redefined to meet the challenges of efficiency, speed, and sustainability. By 2025, the deploying and designing of precast and ‘post-tensioned’ concrete structures are going to dominate the field as designers and engineers embrace new methods to increase durability and freedom of design.…

-

Why Builders Prefer Precast Concrete Rail Fences Over Traditional Wood

Posted :

by :

Introduction Selecting suitable materials has implications for durability, maintenance, and aesthetics. From the options available, precast concrete rail fences are increasingly becoming the favored option for many builders, in place of the wooden fences that were the standard for years. Builders’ preferences for precast over wood and considers the advantages that will continue to influence…

-

Modern Split Rail Fence Designs Using Precast Concrete for Timeless Appeal

Introduction Split rail fences are simple and rustic. They are made of wood rails and posts stacked horizontally. Even though they are simple and rustic, they need upkeep to prevent rotting, warping, and pest damage. Split rail fences made of precast concrete don’t suffer from the same issues. They mimic the wood design but are…

-

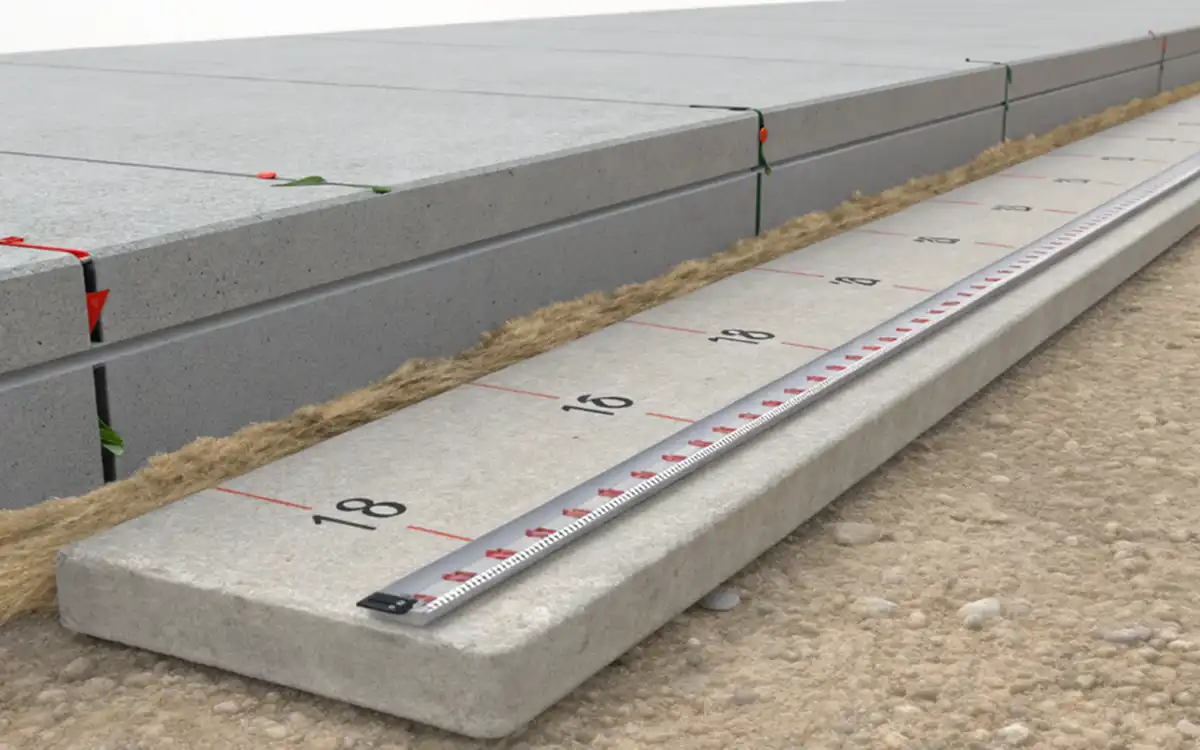

How to Find Linear Feet for Precast Concrete Projects: A Builder’s Easy Guide

Posted :

by :

Introduction How to Find Linear Feet? Precast projects require careful budgeting, planning, and estimating installations. Calcultations on linear feet for any type of precast construction is one of the most important. Understand the concept of linear feet for building concrete fences, walls, or any other precast elements ensures cost effective construction, minimimizing project delays, and…

-

Precast Concrete Wall Repair: The Ultimate Guide for Homeowners

Posted :

by :

Introduction Precast concrete wall repair are made under controlled conditions which leads to greater durability and consistency when compared to walls made using onsite poured concrete. This is why they have become increasingly popular to use for fences, boundary walls, and even structural walls. Cracks and deterioration are inevitable over time, whether it is due…

-

Wall Crack Repair Made Easy: Why Precast Concrete Is the Ultimate Solution

Posted :

by :

Introduction No one wants to see wall crack repair forming in the walls of a building. No matter how small these might be, all of them diminish the aesthetics of a building, not to mention the potential underlying problems they pose. Incomplete repairs might include patching, sealing, and piercing plaster, and they might save the…

-

Precast Concrete Blockwork Walls: 6 Benefits That Make Them a Builder’s Favorite

Posted :

by :

Introduction The modern construction landscape places unrivaled emphasis on speed, strength, and quality. Builders strive for solutions that achieve both durability and efficiency. Precast concrete blockwork walls have become one of the foremost construction technologies of 2025. From builders’ working on residential homes to large commercial undertakings, these walls have become their number one option.…

-

Precast Concrete Fence: 6 Stunning Benefits That Redefine Modern Boundaries

Posted :

by :

Introduction As we look ahead to 2025, new advancements in building tech will continue to remodel our world’s buildings and how we think about fences. Over the past couple of years, the precast concrete fence has emerged as a strong, modern, and more environmentally friendly option to wooden and metal fences. These fences are changing…