Category: News

-

Concrete Wall Retaining: 7 Stunning Precast Designs Transforming Modern Landscaping

Posted :

by :

Introduction In the present day, concrete wall retaining structures have gained great importance in landscaping and construction for the consideration of erosion control, attractive terraces, and maximizing usable space outdoors. As modern-day landscaping focuses on sustainable and economical methods, precast concrete is now a leading choice. Unlike poured concrete walls, retaining walls made from precast…

-

Precast Prestressed Concrete Institute: 7 Game-Changing Innovations Transforming Modern Construction

Posted :

by :

What is the Precast Prestressed Concrete Institute? Started in 1954, the Precast Prestressed Concrete Institute is a technical organization which provides support to producers, engineers, architects, educators, and contractors in the industry of precast and prestressed concrete. PCI fosters the excellence in the manufacture and utilization of precast concrete by developing standards, design handbooks, quality…

-

Things to Do in Riverside: 7 Amazing Experiences from Historic Sites to Modern Precast Concrete Designs

Posted :

by :

Introduction Riverside, California, is a city with its roots intertwined with innovation. Its history is multifaceted, with historic sites and modern constructs where elaborately designed precast concrete has become a prominent feature. If you fancy history, the outdoors, or the latest structures, there is so much to do and see in things to do in…

-

Precast Concrete Wall Panels: 7 Powerful Ways They Transform Modern Building Design

Posted :

by :

Intro As technology moves forward, construction has precast concrete wall panels that seems to revolutionize the construction industry. Unlike traditional concrete methods, that offers great speed, quality, and sustainability, these panels are made in controlled factory settings and then assembled onsite. There are still innovations being made that extend to 2025, precast concrete will continue…

-

When Was Concrete Invented? 5 Powerful Origins That Inspired Modern Precast Concrete

Posted :

by :

Introduction when was concrete invented? Concrete has become one of the foundation stones of modern construction due to its strength, durability, and versatility. The history of concrete spans thousands of years. When concrete was invented, how concrete was used, how it became what it is today is what I am going to tell you in…

-

Building Mercy Health West with Precast Concrete: A Modern Construction Approach

Posted :

by :

Introduction Mercy Health West stands as a symbol of forward-thinking healthcare facility development, combining state-of-the-art medical services with advanced construction technologies to meet modern community needs. In recent years, especially with updates as of 2025, hospitals and large medical complexes have moved towards innovative solutions to ensure their structures offer durability, aesthetics, efficiency, and resilience…

-

Property Line Protection Made Easy with Precast Concrete Walls for Ultimate Privacy

Posted :

by :

Introduction Protecting the property line is crucial for both privacy and security, especially as urban living density increases and property boundaries become more significant. Traditional boundary options can be expensive, slow to install, and often require frequent maintenance. Enter precast concrete walls, a rapidly growing trend transforming how properties in places like El Monte are secured and…

-

Precast Concrete Finishes: 5 Transform Modern Architecture

Posted :

by :

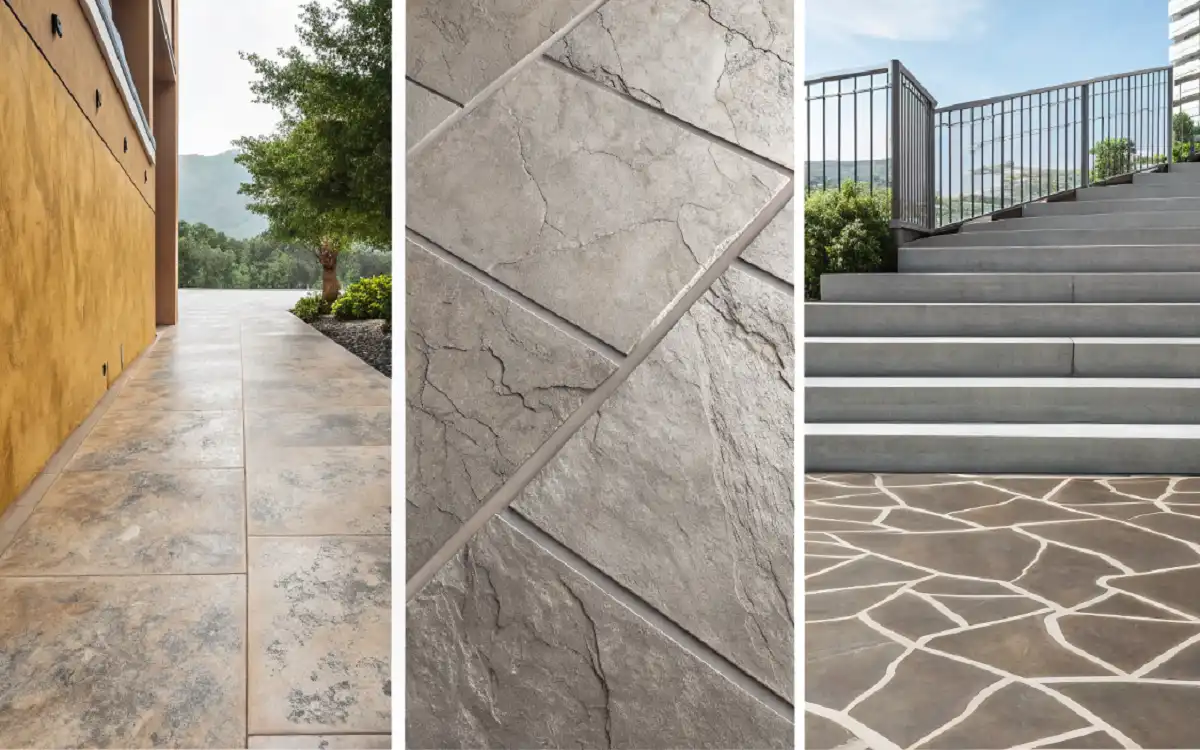

Introduction The use of modern architecture with sustainable and striking materials and methods is underway in the construction of buildings and other structures. An example is in the innovative custom precast concrete finishes. Concrete is fast becoming the creative focus of many architects as advanced technology sprouted concrete ‘artworks’. Smart technology coupled with 3d printing…

-

Precast Concrete Wall Designs: Durable, Stylish, and Cost-Effective

Intro: why do concrete walls do more than just define the perimeter? Every construction project needs to erect walls for the sake of security, supporting frameworks, or delineating boundaries. Walls are usually constructed on site using poured or placed concrete, which are then polished, though this technique involves more shortcomings than benefits. It’s time-consuming and…

-

How Concrete Forms Shape the Future of Precast Concrete?

Introduction In the construction industry, the use of concrete forms especially in the precast concrete sector, is critical. The year 2025 is just around the corner, and because of the fast advancement in technologies, concrete forms technology is rapidly changing. This is evident in the increasing demand of urban developments, as well as incorporating the…