Tag: property line

-

Precast Structures: 9 Reasons They’re Revolutionizing Modern Construction

Posted :

by :

Introduction Modern buildings and infrastructures are starting to adapt precast structures. This remarkable change in design and construction is due to a unique feature in the construction of precast concrete. Precast concrete means concrete elements are constructed in a factory and then transported to the site for assembly. This innovative approach demonstrates undeniable advantages over…

-

Precast Concrete Panels: 7 Smart Benefits Every Builder Should Know

Posted :

by :

Introduction Building materials have a profound effect on the quality, duration, and cost of a project in the rapidly changing construction sector. Precast concrete panels are one of the foremost materials leading this change. These panels, made in a factory and brought to a construction site, are more advantageous than the traditional methods that use…

-

Why Recycled Concrete Is Transforming Precast Projects in 2025

Posted :

by :

Introduction The construction industry is rapidly shifting to circular, more sustainable, and more eco-friendly standards and recycling practices to meet the growing demand for sustainable development worldwide. Particularly in precast applications, the use of recycled concrete is one of the most important advancements in sustainable construction innovations. Recycled concrete meet. The economic needs of contractors…

-

Precast Concrete Walls: 7 Powerful Reasons They Outperform Traditional Walls

Posted :

by :

Introduction Today’s constructions need to be built fast, built strong, and built sustainably, and offer economically viable building solutions. Builders, architects, and property owners are showing a preference for precast concrete walls for the growing number of advantages building to positive customer perceptions. In 2025, the positive sentiments are predicted to grow and be driven…

-

Block Wall Construction: 7 Incredible Benefits of Precast Concrete in 2025

Posted :

by :

Preface There are numerous precast concrete applications in construction. In 2025, new materials continue to change how buildings are designed, and constructed. This innovation in wall construction incorporates precast concrete, enabling block walls to be constructed quicker and at a reduced cost. Contractors continue to marvel at the rapid construction of block walls using precast…

-

Precast Prestressed Concrete Institute: 7 Game-Changing Innovations Transforming Modern Construction

Posted :

by :

What is the Precast Prestressed Concrete Institute? Started in 1954, the Precast Prestressed Concrete Institute is a technical organization which provides support to producers, engineers, architects, educators, and contractors in the industry of precast and prestressed concrete. PCI fosters the excellence in the manufacture and utilization of precast concrete by developing standards, design handbooks, quality…

-

Things to Do in Riverside: 7 Amazing Experiences from Historic Sites to Modern Precast Concrete Designs

Posted :

by :

Introduction Riverside, California, is a city with its roots intertwined with innovation. Its history is multifaceted, with historic sites and modern constructs where elaborately designed precast concrete has become a prominent feature. If you fancy history, the outdoors, or the latest structures, there is so much to do and see in things to do in…

-

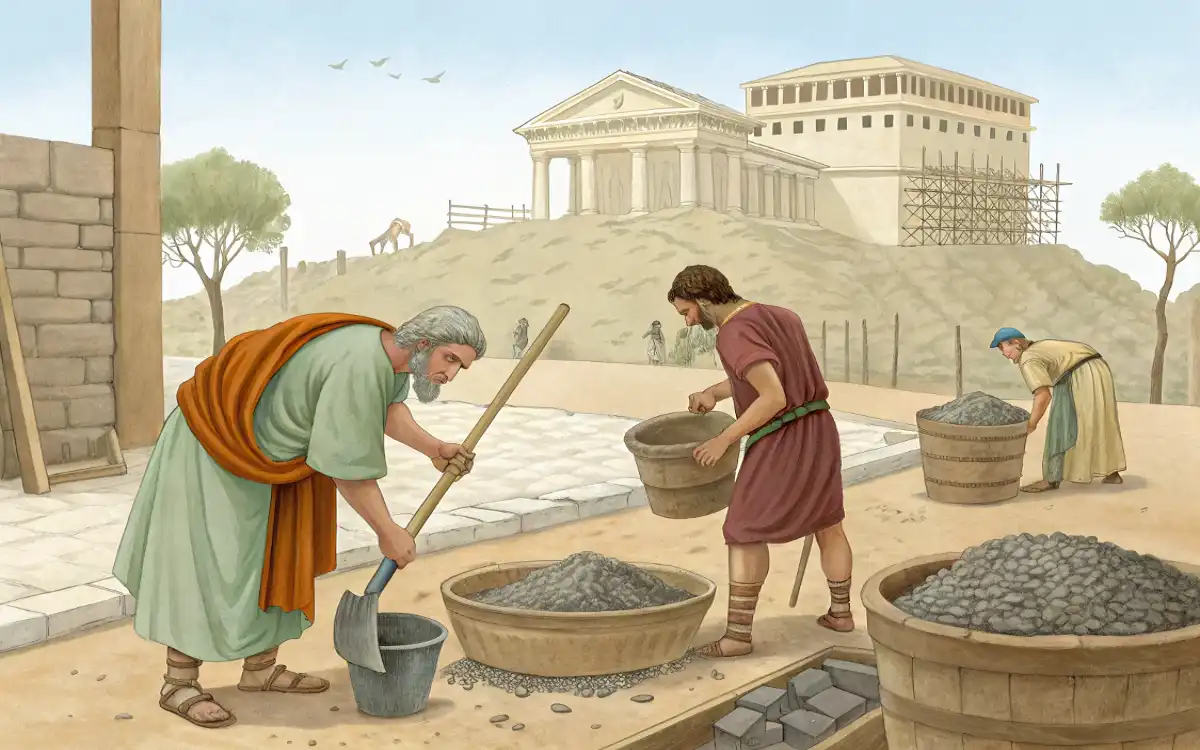

When Was Concrete Invented? 5 Powerful Origins That Inspired Modern Precast Concrete

Posted :

by :

Introduction when was concrete invented? Concrete has become one of the foundation stones of modern construction due to its strength, durability, and versatility. The history of concrete spans thousands of years. When concrete was invented, how concrete was used, how it became what it is today is what I am going to tell you in…

-

El Monte California Precast Concrete: Powerful Ways It’s Transforming Modern Construction

Posted :

by :

Introduction The construction industry in El Monte, California is undergoing dynamic changes as massive advantages come from the versatile nature of precast concrete. The businesses that are trying to build and develop facilities with massive speed and low costs will find great virtue in the advantages provided by precast concrete. Along with its efficiency, strength,…

-

Building Mercy Health West with Precast Concrete: A Modern Construction Approach

Posted :

by :

Introduction Mercy Health West stands as a symbol of forward-thinking healthcare facility development, combining state-of-the-art medical services with advanced construction technologies to meet modern community needs. In recent years, especially with updates as of 2025, hospitals and large medical complexes have moved towards innovative solutions to ensure their structures offer durability, aesthetics, efficiency, and resilience…