Tag: how to find linear feet

-

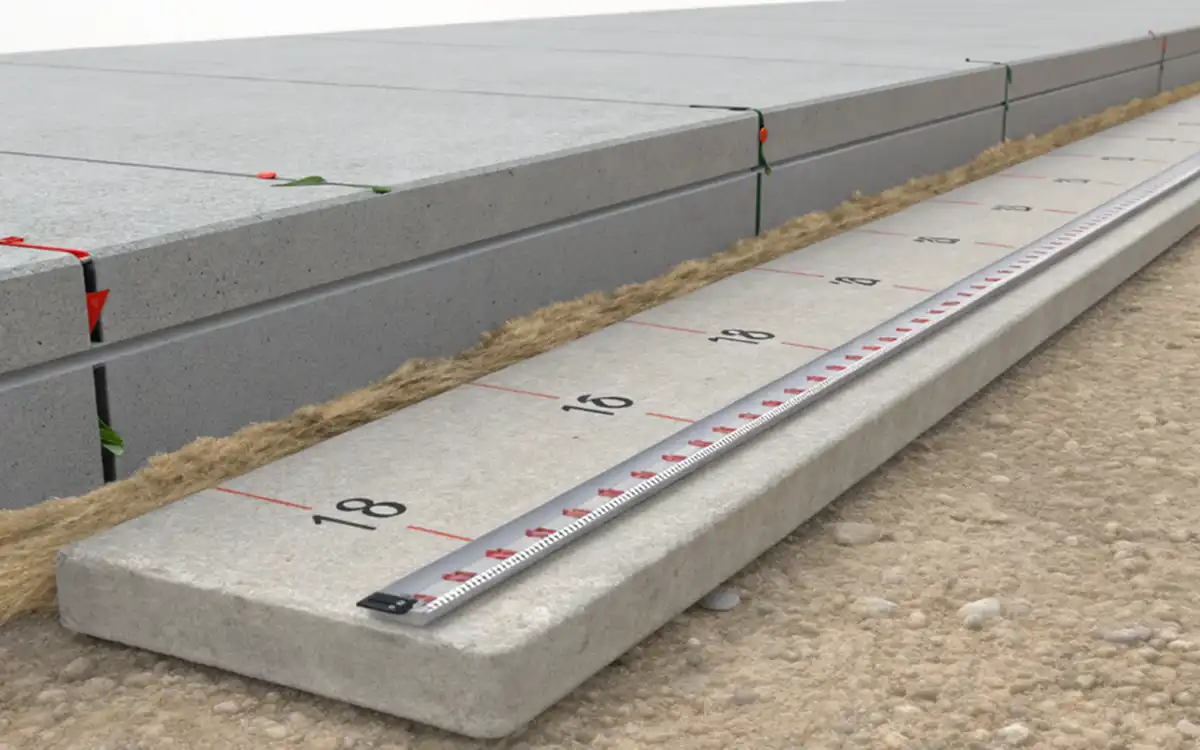

How to Find Linear Feet for Precast Concrete Projects: A Builder’s Easy Guide

Posted :

by :

Introduction How to Find Linear Feet? Precast projects require careful budgeting, planning, and estimating installations. Calcultations on linear feet for any type of precast construction is one of the most important. Understand the concept of linear feet for building concrete fences, walls, or any other precast elements ensures cost effective construction, minimimizing project delays, and…

Recent Posts

Recent comments

No comments to show.