Tag: el monte

-

Precast Concrete Fence: 6 Stunning Benefits That Redefine Modern Boundaries

Posted :

by :

Introduction As we look ahead to 2025, new advancements in building tech will continue to remodel our world’s buildings and how we think about fences. Over the past couple of years, the precast concrete fence has emerged as a strong, modern, and more environmentally friendly option to wooden and metal fences. These fences are changing…

-

Tilt Up Construction vs Precast Concrete: 7 Powerful Differences Builders Must Know

Posted :

by :

In the world of concrete construction, tilt up construction and precast concrete offer different characteristics, advantages, and disadvantages relative to project costs, speed of completion, durability, and design options. Builders need to understand the differences to select the appropriate construction method for the building project in question. Seven salient differences regarding tilt up construction vs…

-

Why Precast Beats Cast in Place Concrete for Modern Construction?

Posted :

by :

Introduction One of the top strategies for success in the construction industry is picking the right method of forming concrete. Between precast concrete and cast in place concrete, the latter being the traditional method, precast concrete is the method of choice in modern constructions, including places like El Monte that prioritize quality and efficiency. This…

-

Why Clayton Concrete Leads in Precast Excellence Across the USA?

Posted :

by :

Introduction to Clayton Concrete’s Industry Leadership Founded in 1951, Clayton Concrete has emerged as one of the premier ready-mix and precast concrete producers in the country. Its technology and quality control focus, along with impeccable customer service, has Clayton Concrete served to all types of construction, be it infrastructure or commercial, throughout the United States.…

-

Precast Solutions in USA: 7 Shocking Reasons Builders Are Switching Introduction

Posted :

by :

To build a thing means to put together different parts of something in order to make it whole and useable. In this case, a concrete component is what is defined as a singular unit of a construction as component parts. In the USA, the concrete in use is most often precast as it has been…

-

Block Wall Construction: 7 Incredible Benefits of Precast Concrete in 2025

Posted :

by :

Preface There are numerous precast concrete applications in construction. In 2025, new materials continue to change how buildings are designed, and constructed. This innovation in wall construction incorporates precast concrete, enabling block walls to be constructed quicker and at a reduced cost. Contractors continue to marvel at the rapid construction of block walls using precast…

-

Precast Prestressed Concrete Institute: 7 Game-Changing Innovations Transforming Modern Construction

Posted :

by :

What is the Precast Prestressed Concrete Institute? Started in 1954, the Precast Prestressed Concrete Institute is a technical organization which provides support to producers, engineers, architects, educators, and contractors in the industry of precast and prestressed concrete. PCI fosters the excellence in the manufacture and utilization of precast concrete by developing standards, design handbooks, quality…

-

Things to Do in Riverside: 7 Amazing Experiences from Historic Sites to Modern Precast Concrete Designs

Posted :

by :

Introduction Riverside, California, is a city with its roots intertwined with innovation. Its history is multifaceted, with historic sites and modern constructs where elaborately designed precast concrete has become a prominent feature. If you fancy history, the outdoors, or the latest structures, there is so much to do and see in things to do in…

-

Precast Concrete Wall Panels: 7 Powerful Ways They Transform Modern Building Design

Posted :

by :

Intro As technology moves forward, construction has precast concrete wall panels that seems to revolutionize the construction industry. Unlike traditional concrete methods, that offers great speed, quality, and sustainability, these panels are made in controlled factory settings and then assembled onsite. There are still innovations being made that extend to 2025, precast concrete will continue…

-

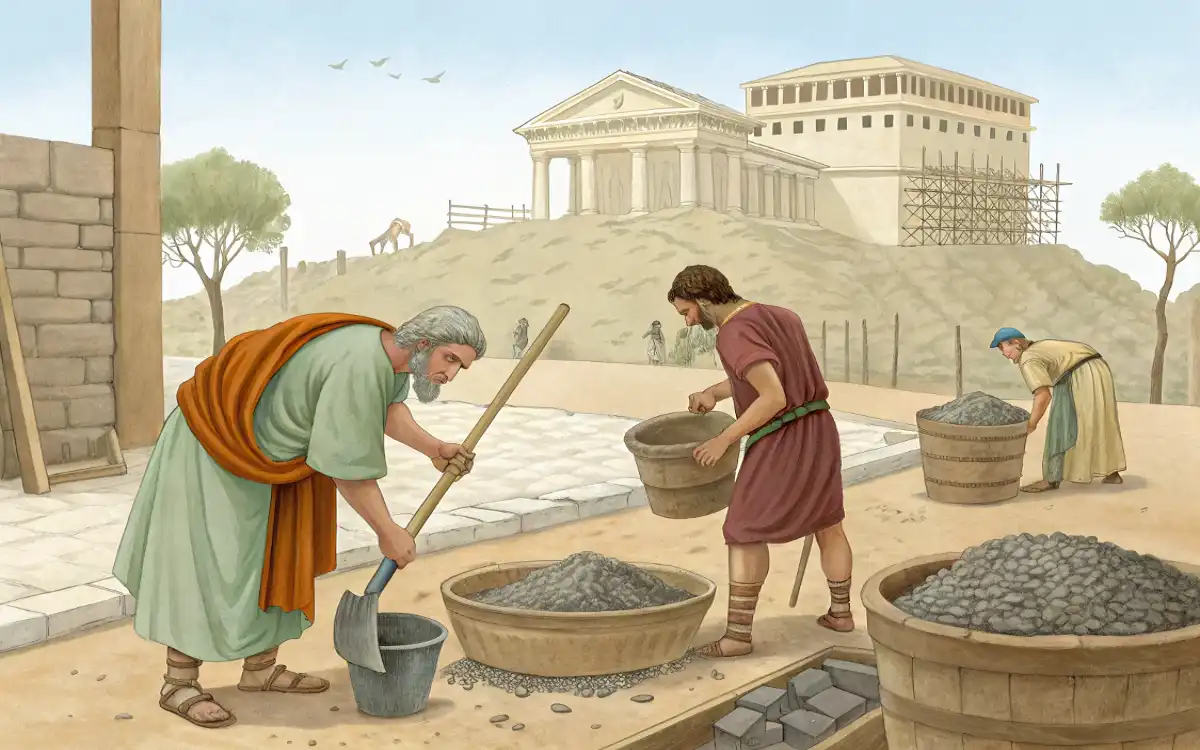

When Was Concrete Invented? 5 Powerful Origins That Inspired Modern Precast Concrete

Posted :

by :

Introduction when was concrete invented? Concrete has become one of the foundation stones of modern construction due to its strength, durability, and versatility. The history of concrete spans thousands of years. When concrete was invented, how concrete was used, how it became what it is today is what I am going to tell you in…