Tag: concrete finishes

-

Precast Concrete Wall Panels: 7 Powerful Ways They Transform Modern Building Design

Posted :

by :

Intro As technology moves forward, construction has precast concrete wall panels that seems to revolutionize the construction industry. Unlike traditional concrete methods, that offers great speed, quality, and sustainability, these panels are made in controlled factory settings and then assembled onsite. There are still innovations being made that extend to 2025, precast concrete will continue…

-

El Monte California Precast Concrete: Powerful Ways It’s Transforming Modern Construction

Posted :

by :

Introduction The construction industry in El Monte, California is undergoing dynamic changes as massive advantages come from the versatile nature of precast concrete. The businesses that are trying to build and develop facilities with massive speed and low costs will find great virtue in the advantages provided by precast concrete. Along with its efficiency, strength,…

-

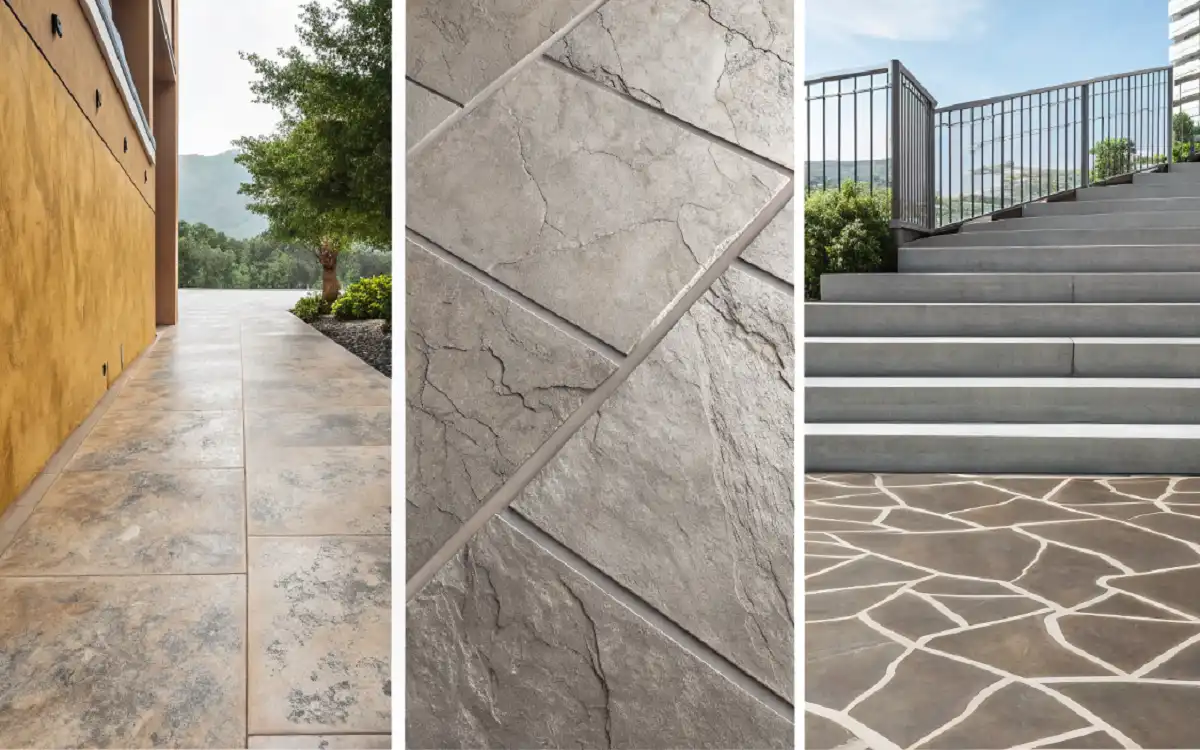

Precast Concrete Finishes: 5 Transform Modern Architecture

Posted :

by :

Introduction The use of modern architecture with sustainable and striking materials and methods is underway in the construction of buildings and other structures. An example is in the innovative custom precast concrete finishes. Concrete is fast becoming the creative focus of many architects as advanced technology sprouted concrete ‘artworks’. Smart technology coupled with 3d printing…