Intro: why do concrete walls do more than just define the perimeter?

Every construction project needs to erect walls for the sake of security, supporting frameworks, or delineating boundaries.

Walls are usually constructed on site using poured or placed concrete, which are then polished, though this technique involves more shortcomings than benefits.

It’s time-consuming and the end product is of variable quality which is directly affected by onsite weather and construction site conditions.

Walls built using precast concrete are designed, manufactured, and polished at factory locations. When under favorable conditions, walls are manufactured in a much shorter time, and the end product is of higher quality.

There’s no denying the concrete walls are way more durable than any other wall too. The modern and diverse factories are capable of complying to a wide ranges of designs, allowing for the walls to be customized too.

It saves money and is more visually appealing than other designs. Whether for residential, commercial, or industrial work, the walls are a win-win.

The Long Lasting Nature of Precast Concrete Walls

Concrete walls are much more durable than concrete floors due to how and where they are made. Concrete floors are made at the construction site and definitely do not have the advanced capabilities of the concrete wall factory.

Rather than losing humidity and heat and being exposed to the outside environment at the construction site, inferior concrete gets poured.

The concrete portions of the walls are poured and set in the factory where the temperature, humidity, and chemicals can be controlled, allowing for walls with much greater concrete density. Such walls have greater durable and resist to:

- The cold and heat in addition to heavy rain and snow

- Earthquakes and floods

- Pests and Fires

- Tears and Wear

Concrete walls, when constructed with design precision, can last for decades and will outlast all other construction materials. Walls also do not need much maintenance and are, therefore, more valuable.

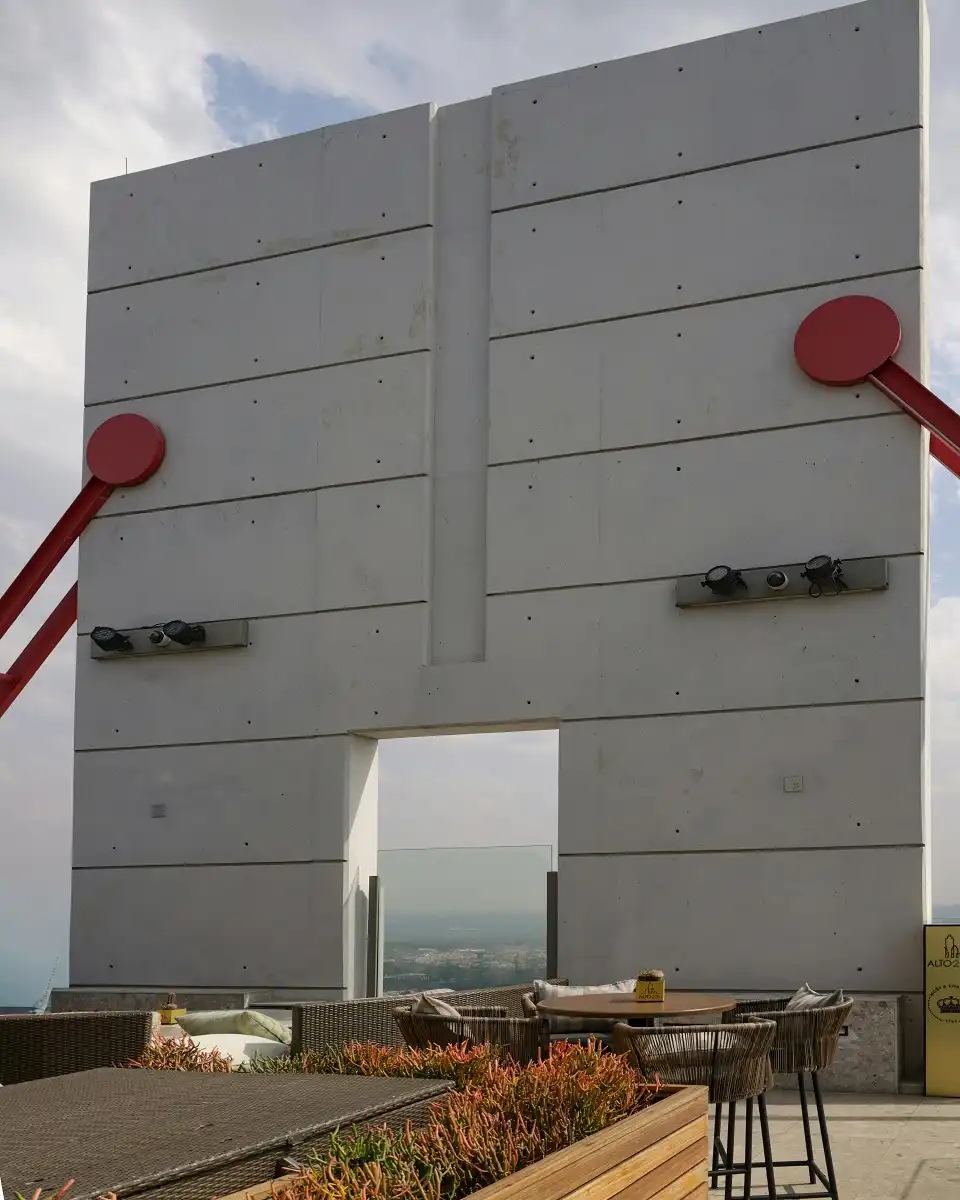

Aside from other construction materials, walls can also be designed to be visually idyllic as well as sturdy. Advanced techniques in machining and completing walls can make concrete walls appear to be made of much more traditional materials. Walls can also mimic the textures of other materials to make construction easier.

Below are some of the more common design choices

- Surfaces that are textured, or that have patterns, that provide additional interest

- Colored concrete, to coincide with the design or make use of the brand colors.

- Finer, smoother finishes that complement sophisticated styles

- Custom tailored project shapes of various dimensions

The adaptability of the designs means that the concrete slabs will architecturally complement the designs sustainably. This balance makes them elegant and functional options for boundary walls and building facades.

Cost Perspective of Precast Concrete Walls

Costwise, unlike more conventional approaches to constructing walls, concrete slabs are more economical. This can be attributed to:

- Savings in labor due to timely completion of the installation

- Reduction of material waste plain to see, as the factory works to make precise cuts

- Reduction of total time to complete due to how simple and streamlined construction has become.

- Lower overall repair and maintenance costs for the wall’s lifetime.

The difference in cost per linear foot is something that is often noticeable with concrete walls. While the more conventional construction materials initially cost less, the long-lasting utility of the concrete walls makes them more economical in the long run.

Updates and Trends in 2025

There are advances and developments from year 2025 which are needed and helpful in technology in walls made of precast concrete.

1. Environmentally Conscious Mix Designs

The impact of concrete production has become better as manufacturers incorporate materials like fly ash and slag. Closed loop water recycling and materials also aid in the sustainable practices of concrete production.

2. Smart Technology Integration

The use of embedded sensors and sim cards in walls made of precast concrete allow theses walls to be monitored in real time for health issues. This ensures early detection of stress or damages.

3. Advanced Finishing Techniques

Automated finishing and 3D printing enhance the customization of textures and intricate designs of concrete beyond what is achievable.

4. Energy Efficiency

The insulated wall panels of precast concrete are able to save energy due to their great thermal performance. This also allows buildings to attain green building certifications like LEED.

With these offerings and developments changes in concrete walls for construction and building is a great incentive for thoughtful developers.

Key Uses of Precast Concrete Walls

Precast concrete walls are adaptable and can serve a variety of purposes:

- Boundary and compound walls for residential and commercial properties

- Retaining walls for landscaping and hillside stabilization

- Industrial fencing and security measures

- Walls of buildings of commercial and multi-storey constructions

- Sound walls along freeways and in metropolitan areas

Each application illustrates the benefit of time, strength, and flexibility that can be garnered with printed concrete.

Table: Benefits of Precast Concrete Walls as Compared to Other Walls

| Feature | Precast Concrete Wall | Traditional Concrete Wall |

| Installation Time | Few hours to days | Weeks or months |

| Cost Efficiency | More cost-effective long-term | Higher labor and material costs |

| Strength & Durability | High compressive strength, durable | Moderate, variable quality |

| Aesthetic Options | Wide range: colors, textures | Limited to site finishing |

| Maintenance Requirements | Low maintenance | Medium to high maintenance |

| Environmental Impact | Minimal waste, recyclable | Higher waste and energy usage |

| Customization | Easily customized in factory | On-site adjustments difficult |

| Weather Resistance | Highly resistant to elements | Prone to cracks and erosion |

This table succinctly captures the superior performance and value offered by pre-cast concrete walls as compared to walls built using conventional approaches.

Understanding Concrete Forms in Precast Wall Production

Concrete forms during the production of a wall are of utmost importance. These are molds where the mixture of concrete is poured in order to set in the particular dimension and shape.

Unlike construction in a building site, where concrete is poured directly and is manually and roughly shaped, the ready-made the rest of the wall, the concrete poured in the wall panels forms are repetitively used.

These are made in controlled factory environments. This guarantees that the walls are made with the precise and repeatable measures that are ever required.

Final Thoughts

The year 2025 features precast concrete walls as an optimum combination of strength, elegance, and economy. They are unbelievably strong since they are manufactured and controlled in their factory.

They are also highly customizable in design and can suit any architect’s demands, never violating their artistic sensibility.

Due to further advancements in smart tech and sustainable design, as time moves on, precast concrete walls are becoming ever so prudent and ecologically conscious.

For Repair and Services

1924 W Edward Ln, Milwaukee, WI 53209, United States

Phone: +14142855933

Email: [email protected]

Leave a Reply