Category: blogs

-

Why Precast Concrete Finishing Delivers Better Quality Than On-Site Work

Posted :

by :

Introduction Delivering durable and aesthetic structures within time and budget is the nature of the construction industry. Concrete finishing is the most important process as it determines how well the end product can withstand use and various weather conditions and will also satisfy the aesthetic criteria. Traditionally, concrete finishing done on-site, which is often subject…

-

Precast Concrete Slabs: The Smart Choice for Fast and Durable Construction

Posted :

by :

Introduction By 2025, the construction industry will be challenged like never before to deliver on the trifecta of efficiency, longevity, and sustainability. Precast concrete slabs respond to this challenge with ready-to-install slabs that decrease construction time, lower costs, and improve the quality of the structures built. As automation and “smart” infrastructure integrate advanced urbanization, proof…

-

Top Concrete Contractor Services Transforming America’s Infrastructure

Posted :

by :

Introduction Concrete contractors are vital to maintaining parts of America’s infrastructure as they assist in building and repairing roads and bridges, as well as buildings and facilities. The industry has been expanding rapidly in recent years and these changes are mostly because of recent advancements in innovative concrete technologies, digital practices, and sustainability. Focuses on…

-

Precast Concrete Panels: The Future of Fast and Durable Construction

Posted :

by :

Introduction: A new phase in construction Joisted buildings have become a mainstay in the construction industry due to their speed, strength, and efficacy. Urbanization and tight construction timelines have led builders and developers to use more and more precast concrete panels. Modern architecture applications emphasize the advancement in precast as of 2025. This article will…

-

Why Roads Made of Precast Concrete Last Longer Than Asphalt

Posted :

by :

An Overview Roads Made of necessary for transport and economic activities around the globe. Roads are constructed using different materials and these materials impact the road’s lifespan, amount charged in maintenance, and the cost to the environment. Asphalt and precast concrete are two materials used to construct a road surface. The following will discuss the…

-

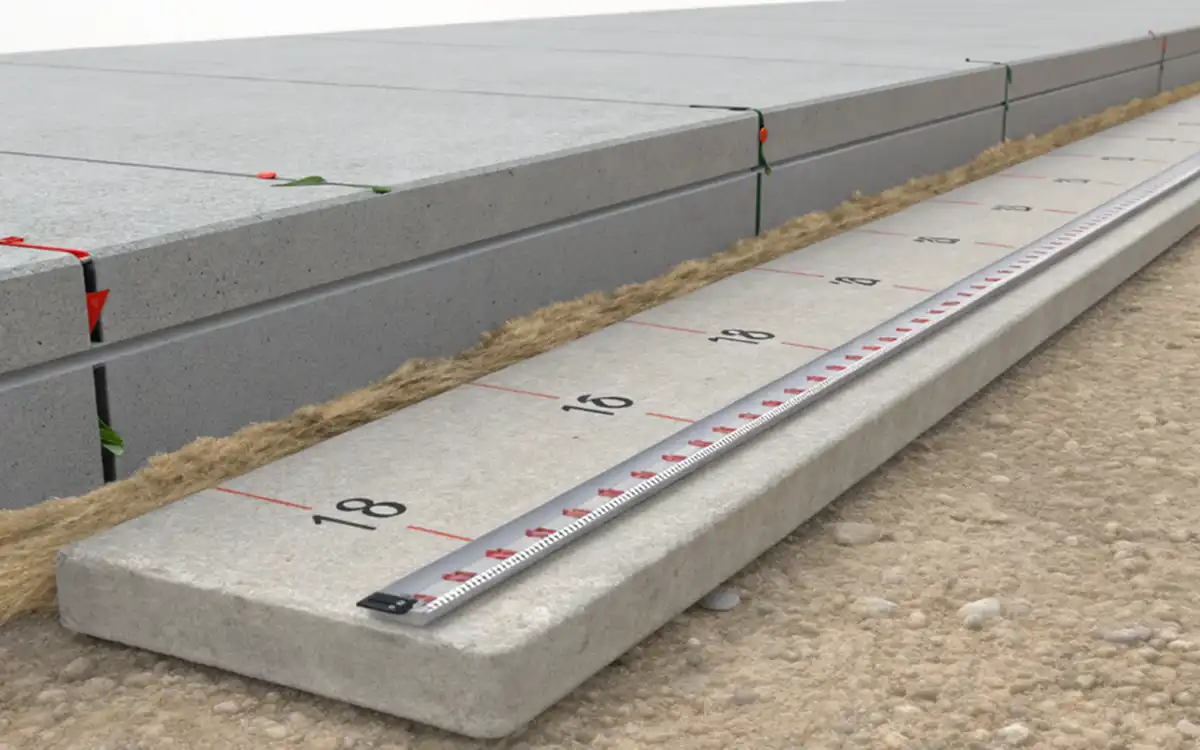

How to Calculate Linear Square Foot in Precast Concrete Projects

Posted :

by :

Getting Started In precast concrete projects, determining materials, dimensions, and measuring Linear square foot is essential for determining project costs, planning materials, and overall project success. Linear square foot combines measurements of linear footage, which is length, and square footage, which is area. Learning how to calculate them provides the basis for determining the estimated…

-

Why Builders Prefer Precast Concrete Rail Fences Over Traditional Wood

Posted :

by :

Introduction Selecting suitable materials has implications for durability, maintenance, and aesthetics. From the options available, precast concrete rail fences are increasingly becoming the favored option for many builders, in place of the wooden fences that were the standard for years. Builders’ preferences for precast over wood and considers the advantages that will continue to influence…

-

Precast Concrete Masonry Walls: The Future of Durable Construction

Posted :

by :

Introduction The construction world is rapidly changing as builders and developers continue to figure out how to make structures stronger, quicker, and more durable. One technique that stands out is the advent of precast concrete masonry walls. These walls, with their unapologetic emphasis on the efficiency, sustainability, and resilience of construction, are mainstreaming the future…

-

Modern Split Rail Fence Designs Using Precast Concrete for Timeless Appeal

Introduction Split rail fences are simple and rustic. They are made of wood rails and posts stacked horizontally. Even though they are simple and rustic, they need upkeep to prevent rotting, warping, and pest damage. Split rail fences made of precast concrete don’t suffer from the same issues. They mimic the wood design but are…

-

How to Find Linear Feet for Precast Concrete Projects: A Builder’s Easy Guide

Posted :

by :

Introduction How to Find Linear Feet? Precast projects require careful budgeting, planning, and estimating installations. Calcultations on linear feet for any type of precast construction is one of the most important. Understand the concept of linear feet for building concrete fences, walls, or any other precast elements ensures cost effective construction, minimimizing project delays, and…